Application of Ammonium Sulfate in the Food Industry: A Comprehensive Guide for Manufacturers

Ammonium Sulfate: From Farm to Table

When we hear the name Ammonium Sulfate, most people immediately think of agricultural fertilizers and increased crop yields. However, the truth is that this chemical is not limited to agriculture; its presence is also seen in various industries, including textiles, pharmaceuticals, and the food industry. In fact, Food Grade Ammonium Sulfate is used as an approved additive in the food industry and plays a significant role in improving product quality.

In international standards such as the FDA (U.S. Food and Drug Administration) and EFSA (European Food Safety Authority), ammonium sulfate is classified as a safe additive (when used in controlled amounts). This compound is most commonly used in the production of bread, cakes, biscuits, and flour-based products, and it is recognized as a Dough Conditioner.

Industrial bread manufacturers in developed countries have long used this compound to improve flour properties, enhance dough quality, increase volume, and improve the texture of the final product. In Iran, with the growth of industrial bakeries, the use of food-grade ammonium sulfate is also expanding day by day.

Chemical Composition and Food-Grade Properties of Ammonium Sulfate

Ammonium sulfate (NH₄)₂SO₄ is an inorganic compound obtained from the reaction of ammonia with sulfuric acid. The main difference between agricultural and food-grade types lies in purity and impurity levels. In food-grade ammonium sulfate, purity must be above 99% and free of heavy metals and industrial contaminants.

This compound is used in the food industry for the following reasons:

pH regulation of dough: Ammonium sulfate can keep the dough environment slightly alkaline, which aids in better fermentation.

Yeast nutrition: Yeasts require nitrogen compounds for activity, and ammonium sulfate provides an excellent source of nitrogen for them.

Improving bread texture: Presence of this compound increases volume, reduces stickiness, and creates a golden, attractive crust.

Increasing product shelf-life: Products made with ammonium sulfate generally stale slower and maintain their quality longer.

Applications of Ammonium Sulfate in the Food Industry

1. Application in Bread and Flour-Based Products

One of the most important uses of food-grade ammonium sulfate in the food industry is in bread production. This compound acts as a dough improver and plays several essential roles:

Yeast nutrition: Ammonium sulfate provides a non-protein nitrogen source for yeast. This accelerates fermentation, increases carbon dioxide production, and results in better dough rise.

Increased bread volume: Breads made with ammonium sulfate have greater volume and appear lighter.

Improved color and taste: The bread crust achieves a better golden color, and the flavor is more balanced.

Reduced staling: Using this compound delays staling of bread.

For this reason, ammonium sulfate is a standard ingredient in many industrial bakery formulations.

2. Application in Pastry and Cake Production

In the pastry industry, ammonium sulfate has a similar role to bread. In the production of cakes, biscuits, and cookies, it is used to improve dough texture, increase volume, and achieve uniform products. Also, by controlling fermentation and chemical reactions, the cake becomes softer and fluffier.

3. Application in Dairy Industry

In some dairy products, especially those that require pH adjustment, small amounts of ammonium sulfate are used. This compound can help maintain stability and the final quality of products. There are also reports of limited use in cheese-making.

4. Application in Beverages

Ammonium sulfate plays an important role in beverage production, particularly in beer and fermented drinks, by providing nitrogen for yeast. Adding controlled amounts helps achieve better and more uniform fermentation, improving flavor quality and foam stability.

5. Application in Food Additives

Ammonium sulfate is registered as an approved additive (E517) in the European Union. It is used in some products as a pH regulator or stabilizer. Care must be taken to use only the permitted amounts, as excessive use may cause issues.

Table Applications of Ammonium Sulfate in the Food Industry

| Food Product | Role of Ammonium Sulfate | Effect on Final Product |

|---|---|---|

| Industrial Bread | Yeast nutrition, dough improvement | Increased volume, reduced staling |

| Cakes and Pastries | Dough regulation, more stable | Softer texture, better rise |

| Beer and Beverages | Provides nitrogen for yeast | Better fermentation, uniform flavor |

| Dairy Products | pH regulation | More stable, consistent quality |

| Food Additives | E517 – pH regulator and stabilizer | Improved physical properties and shelf-life |

Advantages and Disadvantages of Ammonium Sulfate in the Food Industry

Advantages:

Nitrogen source for yeast: Excellent non-protein nitrogen source that enhances yeast activity during fermentation.

Improves bread and cake quality: Increases volume, gives a more golden crust, and softer texture in flour-based products.

Increases product shelf-life: Products stale more slowly and maintain quality longer.

pH regulation and stability: Helps maintain acidity balance in some foods like dairy and fermented beverages.

Globally approved additive: Approved by international organizations such as FDA and EFSA in controlled amounts.

Disadvantages and Limitations:

Requires precise dosage control: Excessive consumption can cause unpleasant taste or digestive issues.

Not widely used in all foods: Only approved for specific products like bread, cakes, and fermented beverages.

Consumer sensitivity to additives: Some consumers prefer products free of chemical additives.

Competition with natural additives: Recent trends favor natural improvers like enzymes and malt.

Comparison with Other Food Additives

Compared to Enzymes:

Enzymes perform a similar role in improving bread and dough quality. The advantage of enzymes is natural origin, but ammonium sulfate is cheaper and more accessible.

Compared to Phosphates:

Phosphates are also used as dough improvers. The main difference is that ammonium sulfate additionally provides nitrogen for yeast.

Compared to Calcium Sulfate:

Calcium sulfate is mainly used to improve dough strength and moisture control, while ammonium sulfate primarily feeds yeast and increases volume.

Safety and Environmental Impact of Ammonium Sulfate in the Food Industry

Human Safety:

Ammonium sulfate, as a food additive (E517), is approved in the EU and other countries. Reputable organizations such as FDA and EFSA have declared its use in controlled amounts safe.

Permitted dosage: Typically only a few hundred milligrams per kilogram of product, which is not hazardous to health.

Potential effects: Overuse may alter flavor or cause digestive issues; hence adherence to safety standards is essential.

Allergenicity: No reports of direct allergy or sensitivity have been published.

Environmental Impact:

Since ammonium sulfate is widely used in agriculture, concerns about soil and water effects exist. However, its use in the food industry, due to very small amounts, has negligible environmental impact.

High solubility: Easily dissolves in water and usually does not remain in industrial wastewater.

Recyclability: With proper wastewater management, ammonium sulfate can even be reused in agriculture.

Eco-friendliness: Compared to some other chemical additives, it poses less environmental risk.

International Regulations and Standards

European Union: Approved as an additive under E517.

United States: Classified as GRAS (Generally Recognized As Safe) by FDA.

Codex Alimentarius: Internationally approves controlled use in food products.

Selecting ammonium sulfate for the food industry is critical because the quality of this additive directly affects consumer health and final product quality. Key factors affecting price and selection include:

Factors Affecting Food-Grade Ammonium Sulfate Price:

Purity percentage: High-purity ammonium sulfate (99% or more) is suitable for food use. Higher purity increases both quality and price.

Country of production: Countries like Iran, China, India, and Turkey produce this product. European and Japanese products are usually more expensive but of higher quality.

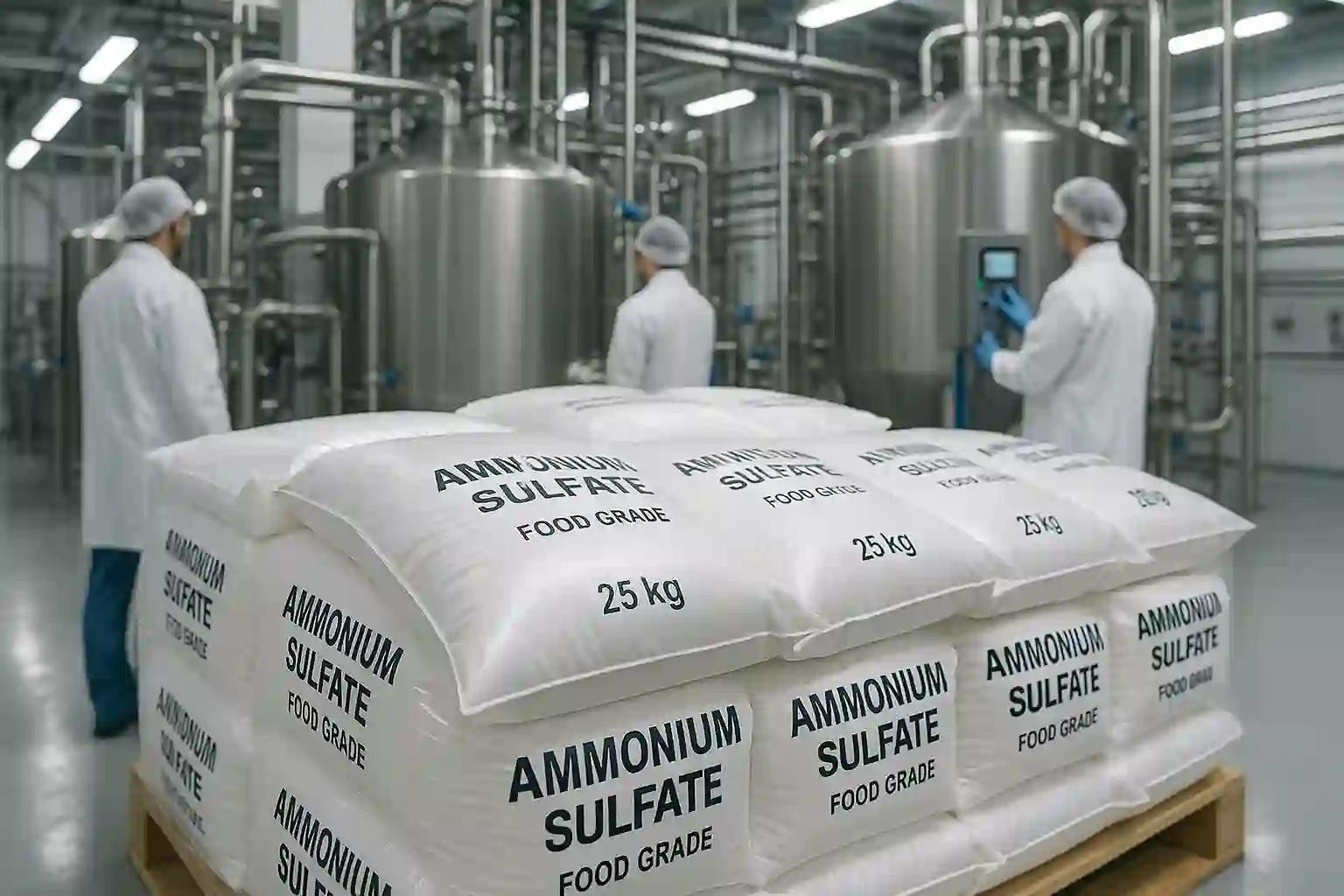

Packaging type: 25 kg packages suit small workshops and factories, while 1000 kg bags are more economical for large industries.

Currency fluctuations and transport costs: Especially in Iran, exchange rate changes directly affect final price. Shipping costs also play an important role.

Important Recommendations for Purchase:

Certificate of Analysis (COA): Always buy from suppliers providing a valid COA, ensuring the product meets food industry standards.

Solubility: The product should dissolve quickly and completely in water to avoid production issues.

Free from impurities: Insoluble impurities can reduce product quality and cause health problems.

Reputable brand: Brands with a strong track record in producing food-grade chemicals are a safer choice.

Guaranteed Quality Food-Grade Ammonium Sulfate from Ammonium Sulfate Brand

The Ammonium Sulfate brand offers products with high purity, stable quality, and standard packaging, making it a reliable choice for the food industry. If you are looking for a safe and approved additive for bread, cakes, fermented beverages, or other food products, this brand is your best companion.

📞 Contact our consultants today to purchase the required ammonium sulfate with competitive pricing and a valid Certificate of Analysis (COA). By choosing us, the quality of your products is guaranteed.