Application of Ammonium Sulfate in the Pharmaceutical Industry

The pharmaceutical industry is one of the most sensitive and advanced scientific and industrial fields in the world, where the choice of raw materials plays a decisive role in the quality, efficacy, and safety of the final products. Among the hundreds of chemicals used in drug production, ammonium sulfate holds a special position. This mineral compound, due to its unique properties, is widely used not only in the production of antibiotics and vaccines but also in the extraction and purification of proteins and enzymes.

In fact, ammonium sulfate, with its high water solubility, strong salting-out effect, and pH-regulating capability, is a multifunctional substance recognized in modern pharmaceutical industries as a strategic tool for enhancing biochemical and chemical processes.

Moreover, the global focus on the production of biotechnology-based and protein drugs has further highlighted the role of this compound. For many researchers and pharmaceutical manufacturers, ammonium sulfate is not just a chemical—it is a bridge between science and industry, enabling the production of more effective and safer medicines.

History of Ammonium Sulfate Use in Pharmaceuticals

The use of ammonium sulfate in pharmaceuticals dates back to the early 20th century, when scientists sought a method to separate proteins and enzymes from complex solutions. This compound quickly became a key tool in biochemistry and pharmaceutical processes due to its unique ability for selective protein precipitation.

One of the most significant historical uses of ammonium sulfate was in protein precipitation, allowing researchers to isolate specific proteins from cellular environments and achieve higher purity for research and drug production. Later, this technique was applied not only in academic research but also in industrial-scale drug production.

In the 1940s and 1950s, alongside the expansion of antibiotic production (e.g., penicillin), ammonium sulfate became an essential additive to improve fermentation and extraction processes, paving the way for modern pharmaceutical manufacturing and establishing its strategic importance.

Today, with advances in biotechnology and modern methods such as chromatography and advanced bioreactors, ammonium sulfate continues to serve as a foundational substance in many stages of biopharmaceutical and vaccine production. Its use persists not only due to its successful track record but also because of proven efficacy and compliance with global standards.

Role and Applications of Ammonium Sulfate in Pharmaceutical Manufacturing

Due to its unique chemical and biological properties, ammonium sulfate is one of the most widely used substances in pharmaceutical and biotechnology industries. It is applied both at laboratory scale and industrial scale, playing a vital role in increasing yield, purity, and stability of pharmaceutical products.

1. Antibiotic Production

Ammonium sulfate is extensively used in the production of antibiotics such as penicillin, streptomycin, and tetracycline. In microbial fermentation, the growth medium requires nitrogen sources and pH control for optimal microbial growth and maximum active compound yield.

Ammonium sulfate serves as a nitrogen source and pH regulator. The nitrogen promotes optimal growth of antibiotic-producing fungi and bacteria, while sulfur contributes to microbial metabolism. Post-production, it assists in extraction and purification, enhancing the final drug purity.

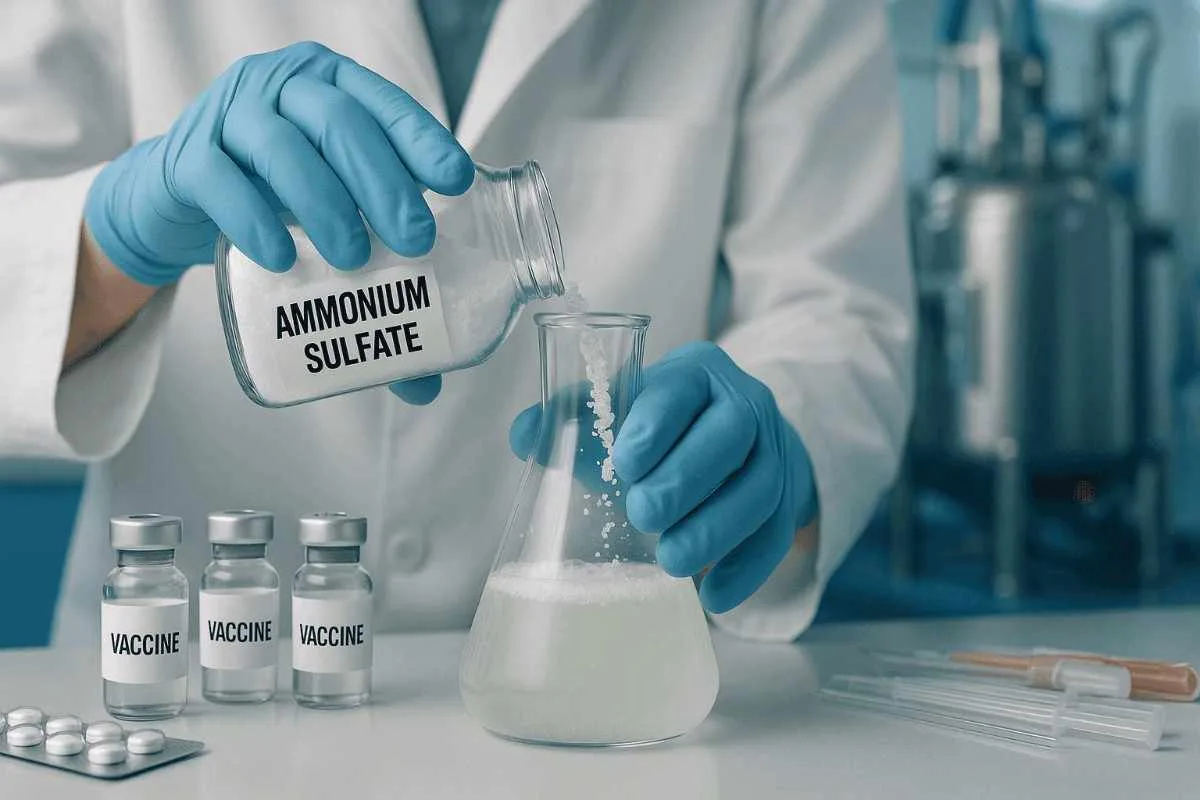

2. Vaccine Production

In vaccine manufacturing, especially protein-based and viral vaccines, advanced techniques are required to isolate and purify antigens. Ammonium sulfate acts as a protein precipitating agent. By increasing the salt concentration in solution, protein solubility decreases, leading to precipitation. This allows manufacturers to isolate target proteins for further purification and stabilization.

Historically, ammonium sulfate was important in vaccines like tetanus and diphtheria, and it continues to play a role in modern recombinant vaccines.

3. Protein and Enzyme Purification

Ammonium sulfate is vital in protein purification for biologic drugs such as insulin, growth hormones, and monoclonal antibodies. Its selective precipitation ability allows the concentration and separation of target proteins in early purification steps. Known as salting out, this method is one of the oldest yet most effective ways to reduce impurities and concentrate desired proteins.

4. Modern Biopharmaceuticals

With the development of biopharmaceuticals, ammonium sulfate’s role has grown. Cultured cells produce large amounts of therapeutic proteins, which need to be separated. Ammonium sulfate is often the first choice for initial protein precipitation. It is also used as a buffer salt in chromatography to stabilize proteins and enzymes during purification.

5. Drug Stability Enhancement

Ammonium sulfate also helps stabilize protein and enzyme drugs. Many proteins are unstable under normal conditions and can denature or degrade quickly. Ammonium sulfate helps maintain protein structure, extending the shelf life of drugs—especially important for those requiring cold-chain storage.

Table Applications of Ammonium Sulfate in Pharmaceuticals

| Application Area | Scientific and Operational Description | Impact Level |

|---|---|---|

| Protein Precipitation | Most common method for isolating proteins in vaccines and antibodies | ⭐⭐⭐⭐⭐ |

| Vaccine Production | As a supportive salt in purification and stabilization of viral and bacterial vaccines | ⭐⭐⭐⭐ |

| Monoclonal Antibodies | Used in early purification steps for therapeutic and research antibodies | ⭐⭐⭐⭐ |

| Pharmaceutical Enzymes | Assists in separation and stabilization at lab and industrial scale | ⭐⭐⭐ |

| Nutraceuticals | Limited use to improve stability of certain supplements | ⭐⭐ |

| Modern Biopharmaceuticals | Plays a role in emerging technologies like drug nanoparticles and biomaterials | ⭐⭐⭐ |

Key Processes of Ammonium Sulfate in Pharmaceuticals

Protein Precipitation (“Salting Out”)

Salt is added to a protein solution.

Protein solubility decreases as salt concentration rises.

Proteins gradually precipitate and separate from solution.

This method is cost-effective and allows rapid, high-yield protein separation, serving as an initial step before advanced purification in protein-based drug production.

Chromatography

Ammonium sulfate is used as:

Buffer salt: Controls pH and stabilizes proteins.

Precipitation aid: Enhances sample loading in chromatography columns.

Types of chromatography where ammonium sulfate is used include:

Ion exchange chromatography

Size exclusion chromatography

These techniques are essential for purifying drugs like insulin and monoclonal antibodies.

Final Purification

After initial precipitation and chromatography, ammonium sulfate helps stabilize protein molecules and prevent aggregation or denaturation, crucial for:

Vaccine antigen separation

Insulin production

Monoclonal antibody purification

Integration with Modern Technologies

Recent innovations include:

Membrane-based precipitation: Better control over protein precipitation.

Hybrid chromatography systems: Combines chromatography and precipitation for efficiency.

Continuous processing: Controlled salt addition for stable and efficient processes.

Advantages and Limitations

Advantages

High efficiency in protein precipitation

Cost-effective compared to many other chemicals

Stable under standard storage conditions

Compatible with classic and modern processes

Relatively safe compared to compounds like ammonium nitrate

Limitations

May alter pH, affecting sensitive proteins

Requires additional purification steps (e.g., dialysis)

Can denature proteins sensitive to ionic strength

Generates high-salt industrial wastewater requiring careful disposal

Comparison with Other Salts

| Compound | Comparison to Ammonium Sulfate |

|---|---|

| Sodium Chloride (NaCl) | Lower protein precipitation power |

| Ammonium Nitrate (NH₄NO₃) | Higher safety risk; rarely used in pharma |

| Sodium Sulfate (Na₂SO₄) | Used as drying agent; lacks precipitation ability |

| Potassium Sulfate (K₂SO₄) | Limited pharmaceutical value |

Ammonium sulfate remains indispensable for protein separation, vaccine production, and biopharmaceuticals.

Economic Impact and Global Market

Cost Reduction:

Using ammonium sulfate for protein precipitation and vaccine production reduces production costs by 20–30% in some facilities.

Global Demand:

Asia (China & India): Largest producers and consumers

Europe: Focused on vaccines and biologics

North America: Strict regulatory standards, moderate usage

Iran has significant production capacity and can supply regional pharmaceutical markets (Turkey, Iraq, UAE).

Future Outlook:

With the growth of biopharmaceuticals and modern vaccines, global demand is expected to grow at 5–7% annually until 2030.

Pharmaceutical Grade Ammonium Sulfate Purchase

Pharma-grade ammonium sulfate ensures:

High purity

Proven efficacy

Competitive pricing

Reliable suppliers provide certified products, standard packaging, and technical support for pharmaceutical manufacturers and research centers.

FAQ

1. Why is ammonium sulfate used in pharmaceuticals?

It selectively precipitates proteins, improving purification in vaccines, antibodies, and enzyme drugs.

2. Is it safe for drug products?

Yes, pharma-grade ammonium sulfate is removed during final purification, posing no risk to consumers.

3. Difference between industrial and pharmaceutical grades?

Industrial grade may contain heavy metals; pharmaceutical grade complies with USP/EP standards.

4. Major users?

Vaccine manufacturers (Pfizer, Moderna, Sinovac), monoclonal antibody producers (Roche, Amgen), and biotech companies.

5. Is it replaceable?

Other salts like sodium sulfate or ammonium nitrate can sometimes be used, but ammonium sulfate remains the preferred choice due to efficiency, cost, and availability.

References for Further Reading: